HICOX Mathias / Magyar Álom

Mátyás Borlóy’s vehicle development company tried several promising initiatives around the change of regime, but their ideas were not followed by commercial success.

“HICOX Kft. Specializes in vehicle development, especially road vehicles. From general design to complete vehicle design, the company deals with prototyping, prototype building, design studies and design models.” This is how Mátyás Borlóy outlined the essence of his company, presenting his vehicles at the 1991 Budapest International Motor Show.

The presented range included three models: the Trabant-based Mathias/Magyar Álom, a UAZ-based Jeep replica and a re-dressed Lancia Stratos replica. It was a glorious moment in the life of this small workshop, which unfortunately also marked a high point: within a short period of time, HICOX stopped its vehicle development efforts.

Since 1982, the workshop has been operating under the name HICOX, and in addition to chassis protection, has been involved in radio installation. Always wondering about innovations, Matthias had heard of someone who had installed a four-stroke engine in Trabant. This idea seriously captured his mind. Finally, by 1983, the idea crystallized: if there was an engine change that required reinforcing the chassis, the Trabant’s body could also be replaced.

After hundreds of drawings and sketches, a small mock-up was made of plaster. Mátyás Borlóy received a frame from a Trabant service center. The Hungarian suppliers, the Salgótarján Flat Glass Factory, the Elzett and the PEMÜ also were involved in the project. Laszlo Rekettye, a talented engineer from Ikarus, one of the developers of the Tecoplan Leo city small car, and Imre Harmath, an outstanding car restorer and bodyworker, joined the small team.

A Fiat tailgate determined the proportions of the vehicle. The Trabant’s two-meter wheelbase was increased by 20 inches (ca. 51 cm); a joint was welded in front of the handbrake. The thresholds were replaced, with the Wartburg fuel tank installed just below the backseat. The taillights and brakes were also borrowed from Wartburg, while the steering was taken from a Zastava. The windshield was made by the specialists of the Salgótarján Flat Glass Factory.

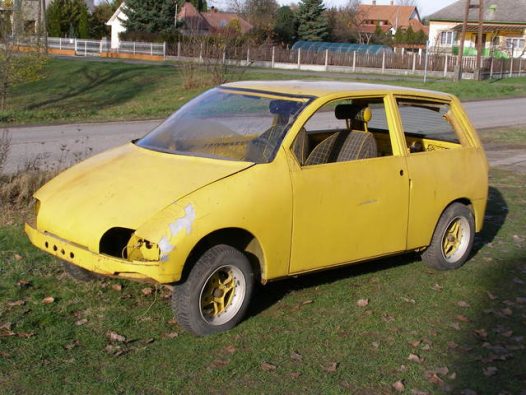

The 47 hp 900 cm³ Fiat 127 engine has been extensively renovated. Finally, after approx. 300,000 forints and thousands of hours of work, in the spring of 1988, a 700-pound plastic body microcar was completed, temporarily named Mathias. The prototype was a huge success at the Motor Show. The fresh winds blowing from politics gave hope to Mátyás. Several newspapers have described the car in great detail, and the car was renamed to Magyar Álom, which meant “Hungarian Dream”.

While the Transport Inspectorate has refused to issue a test order number, saying only vehicle manufacturers can build a car, the police have blinked and ignored the license plate. Ikarus also inspected the HICOX chassis and, with the help of a ministry assistant, began negotiating with the Trabant factory for the delivery of chassis. But in 1990, on a Tuesday, history intervened. This put the project off the agenda.

The HICOX, now in the form of a limited liability company, did not give up the fight. In 1991, they were introduced at the Budapest Motor Show. Meanwhile, Tamás Vadas, a distributor of Oltcits and having excellent relations with the Soviet (and then Russian) companies, built a recreational vehicle for the UAZ based Jeep.

The Mathias / Magyar Álom rested until 2010 in Mátyás Borlóy’s garden. The vehicle in bad condition is currently a part of a private collection dedicated to domestic small cars.